Silicone FX Transparent- transparent moldmaking silicone

is an RTV silicone rubber for two-component addition that vulcanises at room temperature.

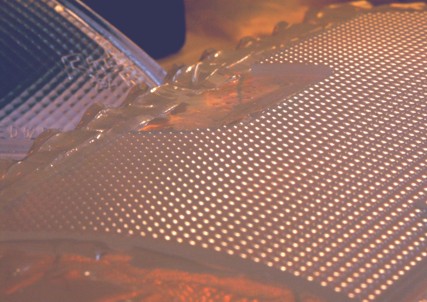

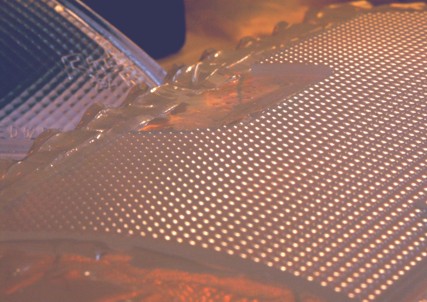

Silicone rubber FX transparent has a high tensile-shear strength, high Shore A, density and a relatively good transparency. It is indispensable in the rapid prototypes production (automotive, industrial design, etc.)

ADVANTAGES

- Excellent chemical and abrasion resistance

- High strength and resistance to tearing

- Low shrinkage

- Dimensional stability

- Temperature resistance up to 200°C

Due to the high viscosity of FX-transparent, vacuuming is recommended.

At temperature 40°C, gelling time and hardening time are cut in half.

APPLICATION AREAS

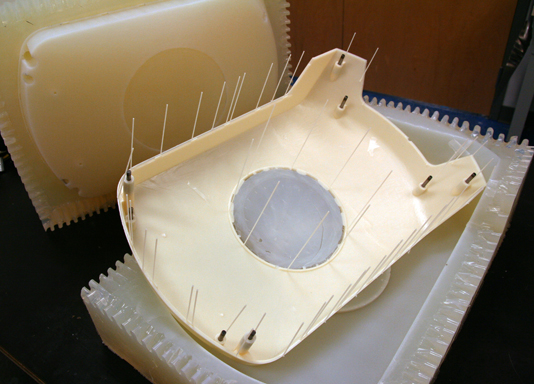

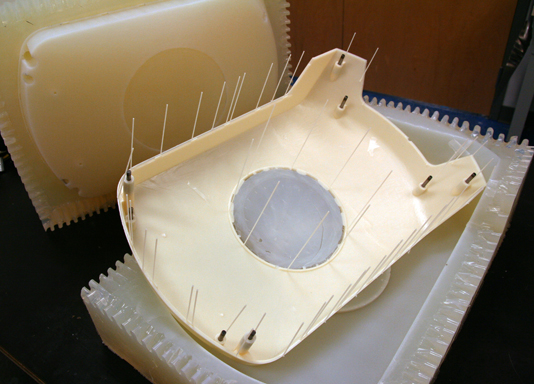

Mouldmaking

Rapid prototyping

Moulds for casting concrete

Making hight accuracy moulds with high chemical resistance

Production of transparent casts

PHYSICAL CHARACTERISTICS

Color: translucent

Viscosity comp. A (10 parts): 70000 cPs

Viscosity comp. B (1 parts): 90 cPs

Viscosity of the precatalysed mixture ≈ 35000 mPas

Mixing ratio: A : B =10 : 1

Density 1.12 g/cc

Pot life at 23 °C: aprox. 90 min

Setting time at 23 °C: aprox. 15 h

Hardness after 24 h: 43 ± 2 sh”A”

Tear strength: > 22 N/mm

Tensile strength: 7,8 ± 0,5 N/mm2

Elongation: 420 ± 20%